Explain the Difference Between Centrifugal and Positive Displacement Pumps

These are used in household pumps for domestic water supply. Positive displacement pumps are used for almost small flow rates.

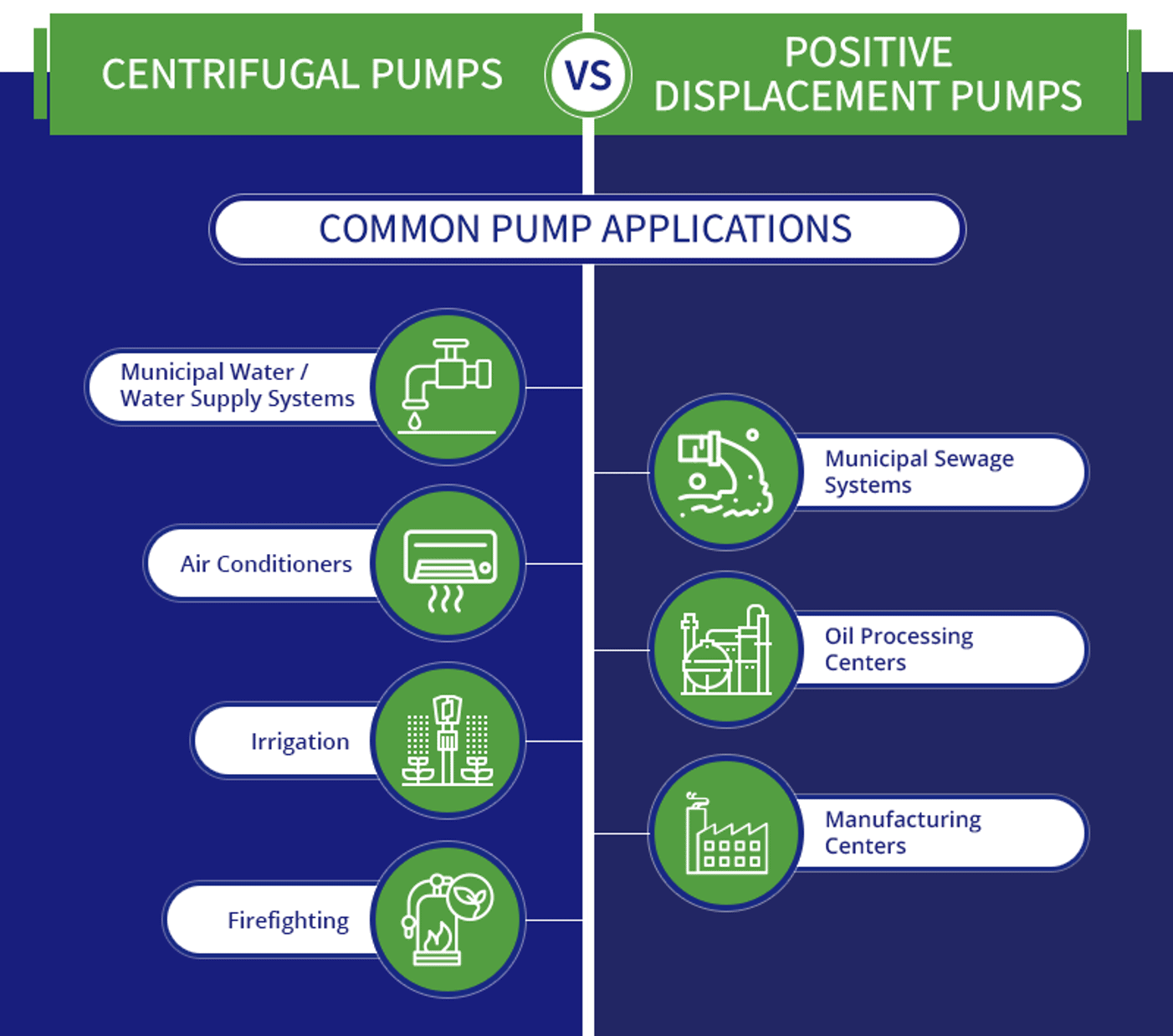

Centrifugal Vs Positive Displacement Pump Pump Types Comparison

The product propylene is transferred to an oxidation unit to change to acrolein 3.

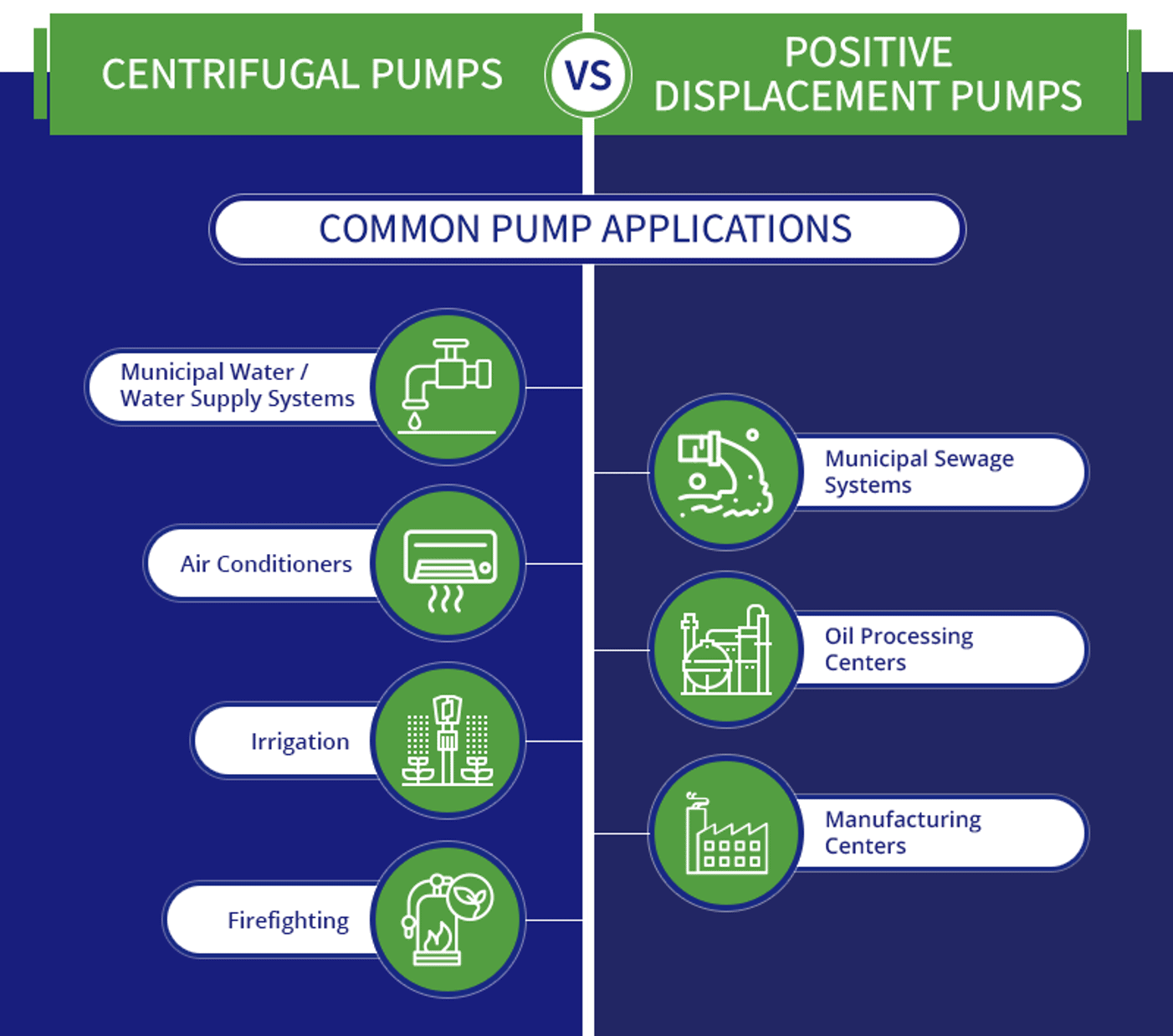

. This type of pump creates an expanding cavity on the suction side of the pump and a contracting cavity on the discharge outlet. Centrifugal pumps dont operate well off the center of their curve. 7 rows Positive displacement pump.

These pumps are used for low force applications and the pressure might be 18 bar to 20 bar. Positive displacement pumps increase the pressure and move the fluid by decreasing the chamber volume in the pump. Viscosity - In positive displacement pumps efficiency increases with increasing viscosity.

In a positive displacement compressor air drawn into a chamber. What is the difference between a Positive Displacement Pump and a Kinetic or Dynamic Pump. In case it operates discharge pipe or the pump will be damaged.

Q2 45 points Draw the Process Flow Diagram PFD for the following chemical process. A positive-displacement pump does not have shutoff head. Horsepower ranges between 05 and 4900 hp.

Positive displacement pumps and dynamic pumps such as centrifugal turbopumps. Explain the difference between a positive displacement compressor and a nonpositive displacement compressor positive dispacement compressors move the gas by taking gas into a space and then replacing that space with something physical like a piston. Non-positive displacement compressors operate like a.

On the other hand efficiency of non. Typical Specification of Positive Displacement Pumps. Widely used for dosing and injection pumps.

A pump is essentially a mechanical device that is used to move a fluid normally uphill or from a tank. The diagram at the left shows a. The difference between positive displacement and non-positive displacement pump mainly include pressure efficiency viscosity performance etc.

The working principle involves an operation that moves fluid by. Centrifugal pump which is also known as rotary pump used kinetic energy of impeller to force the fluid and increase its kinetic energy. Centrifugal pumps are in very widespread use.

Positive Displacement Pump Advantages. Whereas in non-positive displacement pumps efficiency peaks at best-efficiency-point. Reciprocating rotary scroll screw centrifugal.

The most notable example for positive displacement compressors is reciprocating compressor in which air is first drawn into the cylinder. When a positive displacement blower is used movement is caused when a fixed amount of air is trapped and then forced through the discharge pipe. Reciprocating pumps are one of the positive displacement pumps which contain.

Positive displacement compressors move the gas by taking gas into a space and then replacing that space with something physical like a piston. Positive displacement pumps come in two designs. Two Rotary and Two Reciprocating a.

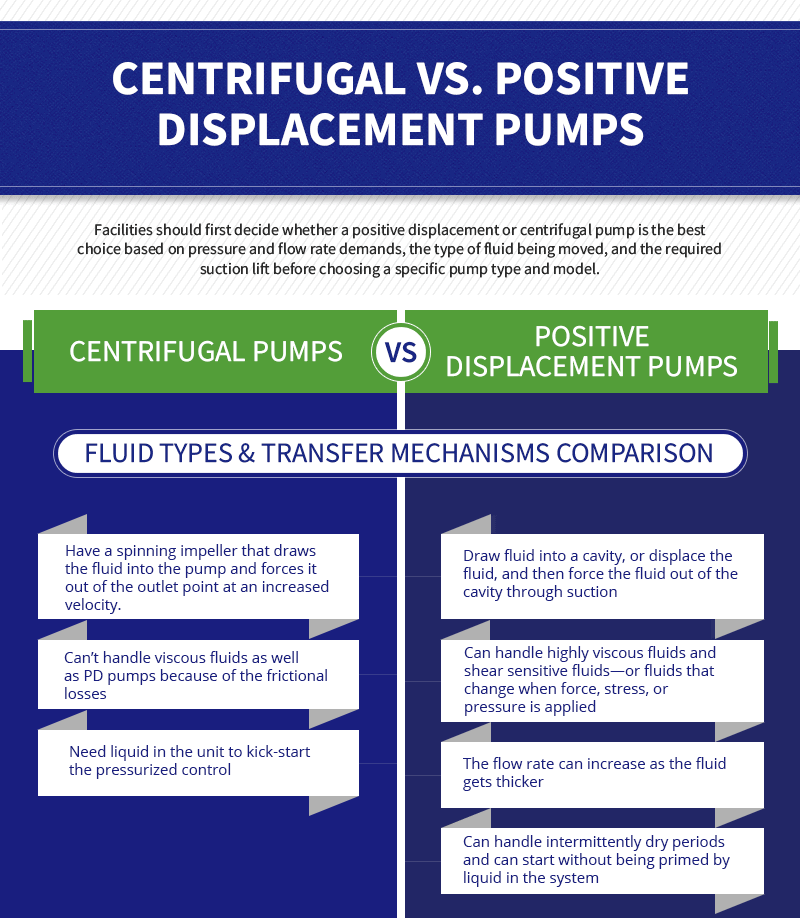

In short with centrifugal pumps pressure is created and flow results whereas with positive displacement pumps flow is created and pressure results. Safety of relief valve is necessary at the discharge side for safety purpose. Explain the difference between a positive displacement compressor and a non- positive displacement compressor.

Positive displacement pumps are generally available to deliver performance in accordance with the following ranges. State Four types of positive displacement pumps. This kinetic energy suddenly converts into pressure energy which move fluid upward.

Flow rates range between 04 to 55000 lpm. Pumps fall into two basic categories. The trapped air then compressed physically reducing the volume of the chamber using any mechanism.

This pump cannot operate at discharge valve closed condition. Steam and propane are added to a reactor 2. Total head pressure ranges between 07 and 6800 Bar.

Differences Between the Centrifugal Pump and Positive Displacement Pump Types of Pumps. Briefly explain the working operation of the four types of positive displacement pumps b. Positive displacement blowers take advantage of positive displacement technology.

These pumps work for high force applications and the force might be 800 bar. As the flow rate remains. Depending on the mechanism used to move the fixed air positive displacement technology can be classified.

At higher or lower pressures efficiency decreases. Due to the fact that the flow is the result of pressure with centrifugal pumps the flow varies with changing pressure. This difference creates pressure which pulls and pushes a fluid simultaneously exerting enough force to create flow.

Q1 10 points What are the differences between centrifugal and positive displacement pumps. Efficiency - In positive displacement pumps efficiency increases with increasing pressure.

Centrifugal Vs Positive Displacement Pump Pump Types Comparison

Centrifugal Vs Positive Displacement Pump Pump Types Comparison

Difference Between Dynamic Positive Displacement Pumps Studentlesso

Comments

Post a Comment